PRODUCTS

Focus on electrical machining machine tools

N series double bull head high speed spark machine

Previous page

Next page

Previous page

Bullhead High Speed Spark Machine - N70

Next page

Description

Peculiarity

●Two head structure, two head can be processed single mold can also be processed at the same time Diversified processing capacity of multiple molds can increase production efficiency by more than 2 times.

●The fixed workbench design and the full box design are adopted, and the dense multi-layer bone-reinforcement ensures that the heavy load time table is not deformed.

●X.Y.Z three-axis using the Swiss factory 45mm "Schneeberger" linear guide where the Z axis uses ball wire rail, more rigid. The X.Y.Z three-axis uses Taiwan imported C5 grade double nut ball wire rod.

●X.Y.Z three axes are used in Japan's original imported "Panasonic" AC servo motor oil pressure automatic lift door.

●Two sets of filter designs.

Specification configuration

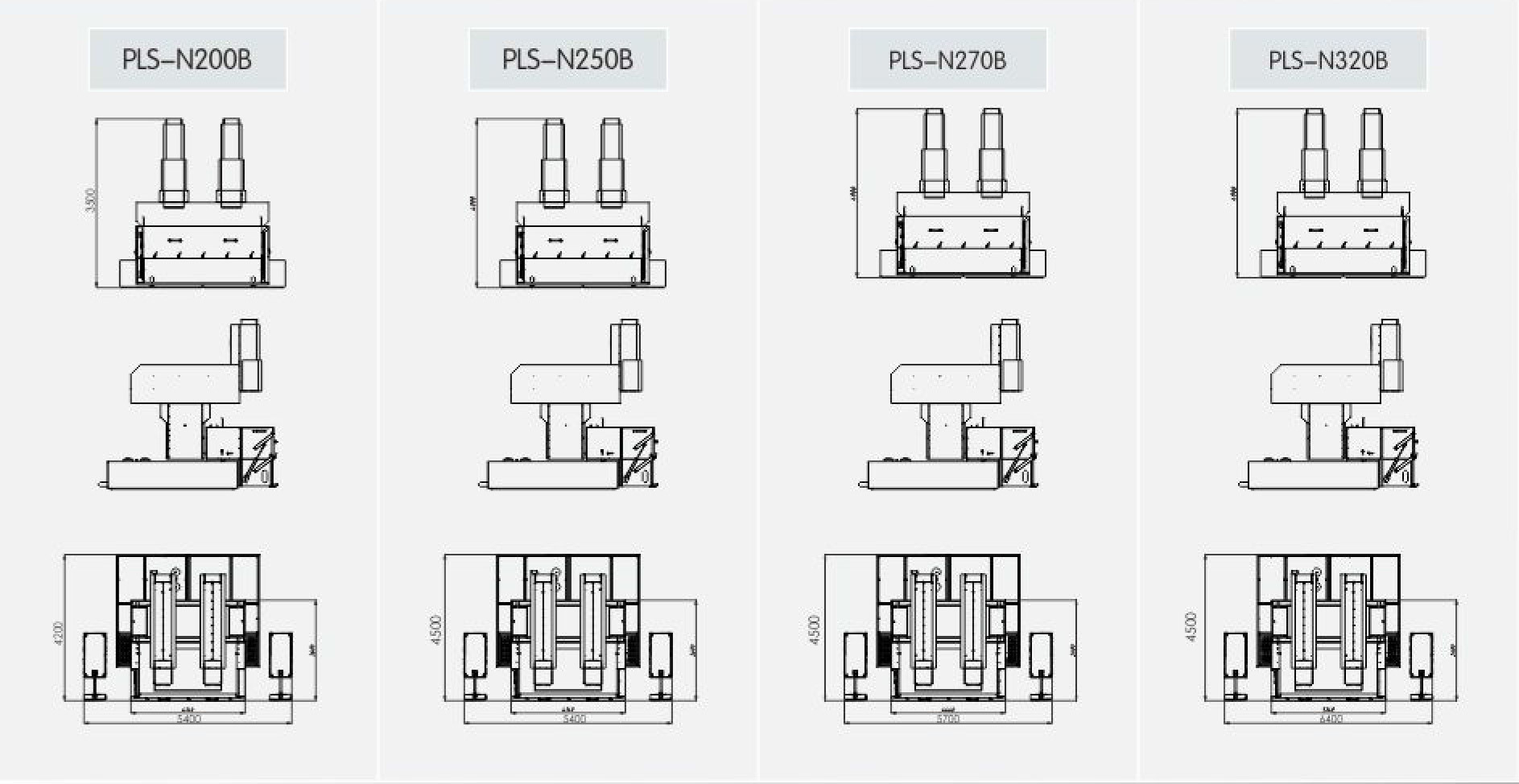

| Model/project | PLS-N200B | PLS-N250B | PLS-N270B | PLS-N320B |

| Working groove inner diameter dimensions(mm) | 3500*1800*850 | 3500*1800*850 | 3800*1800*800 | 4500*1800*800 |

| Table size(mm) | 2000*1000 | 2500*1200 | 2700*1200 | 3200*1200 |

| Work itinerary(mm) | 1200*800*600 | 1450*900*600 | 1750*900*600 | 2400*900*600 |

| Z-wheelbase table high and low points(mm ) | 650-1250 | 650-1250 | 650-1250 | 700-1300 |

| Maximum processed electrode weight(kg) | 450 | 450 | 450 | 450 |

| Maximum workpiece weight for machining(kg) | 12000 | 12000 | 13000 | 15000 |

| XYZ positioning accuracy(mm) | 0.01 | 0.01 | 0.01 | 0.01 |

| XYZ repeatable positioning accuracy(mm ) | 0.002 | 0.002 | 0.002 | 0.002 |

| Minimum drive unit(mm) | 0.001 | 0.001 | 0.001 | 0.001 |

| The weight of the machine tool is approximate(KG) | 15000 | 18000 | 20000 | 25000 |

| Fuel tank capacity (L) (standard for oil-immersed type) | 5400 | 5400 | 5600 | 6500 |

| Fuel tank capacity (L) (flush option) | 1400 | 1400 | 1400 | 1400 |

| Machine tool dimensions(mm) | 5400*4200*3500 | 5400*4500*4000 | 5700*4500*4000 | 6400*4500*4000 |

| Electromechanical integrated dimensions(mm) | 4200*4200*3500 | 4200*4500*4000 | 4500*4500*4000 | 5200*4500*4000 |

| Standard configuration | Automatic fire extinguishing device, electrode chuck, filter element, toolbox, help book, work light | |||

| Optional configuration | EDM fluid, flexible quick fixture, magnetic chuck cup | |||

* Standard configuration and optional configuration vary according to different versions. In line with the principle of continuous development of products. our company reserves the right to change the technical parameters, equipment, optional parts and colors of products at any time.

* This parameter sheet provides general information and is not intended as a contractual document.

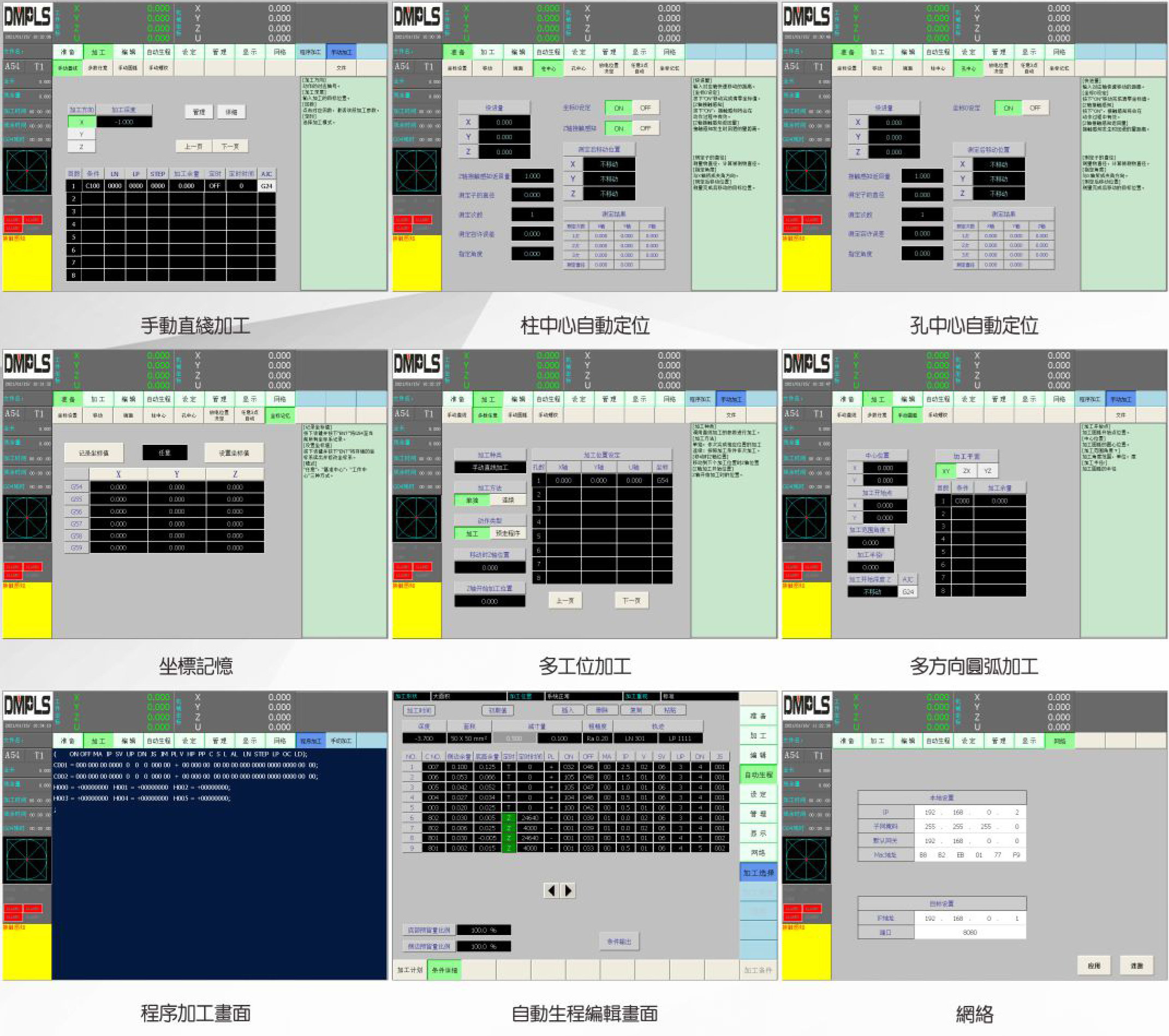

Operating system

CNC power configuration

| Basic parameters | |

| Elecric power | Standard 50A (I00A optional) |

| Input mode | Keyboard, mouse, touch screen |

| Display moe | 15"LCD |

| Driving type | Digital AC servo chive AC |

| NC instruction | Generic G code |

| Discharge function | |

| Basic discharge function | Manual straight line, most processing. arc processing thread processing. Qutomatic raw process processing |

| Processing time accumulation function | When discharging. the system will outomatlically accumulate the total amount |

| Short rewind after single sectian processing | AI the end of single stage processing. you con custormize short backoff distance |

| Processing depth, allowance dispilay | Target depth and remaining depth can be displayed during machining |

| Modify dscharge parameters in real time | Parameter can be modilied without pausing during discharge |

| Manwal - linear multi-axis machining | Manual。Inear machining screen supports mulli-cois machining |

| Automatic production process processing | Multi-drection automalic generating dicharge function |

| Miulti-positionX, Y, 2 Qxis machining | Lateral support tor multi-posifion machiningSupport multi- plane arC processing |

| ArC procesing | Support multi - covity arc processing |

| Pause processing bock to the starting point | When processing is suspended, the original trojectory of the machining axis can be selected to retum to the starting point |

| High speed grophite circult | High-speed graphite processing database |

| MITOf fnish circult | Support miror discharge |

| Special machined circuit | Hard alloy, titanlum aloy, alurminum alloy |

| Intellgent anti-carbon function | If the cartbon deposit is detected. it will automatically go back, and the system will alarm请it exceeds the set value |

| Extend the functionality | |

| Func tion ot electrode lbrary | Support manual data import function |

| Data intertace | Support internet of Things |

| Ful closed loop function | srating scale feedback |

| C onstant temperature electic cabinet | Keep the electric cabinet operating at normal temperature |

| System function | |

| The basic function | Preparation, processing. editing, Qutomatic production process and other tunctions |

| lntellgent positioring function | Integrate the traditional operation mode to improve the efficiency and reduce the cperation |

| Superormal positioning function | Miutti-station location and data storage copacity |

| Ralse knife two level high jump function | Atter timing or cycle lift knife, odd a high jump function |

| Precior compersalion system | Compensate the accuracy error existing in the machinery of make up tor the accurocy error caused by mechanical aging |

| Number ol coordinole syslems | 60sets of Coordinate systems |

| Number of confrol shaft | Three-axis linkage (can support up to seven axes} |

| Fre control system | Segmental probe temperature detection functlion |

| Oill level confrcsystem | Monitor the height of the processing fluid in the tank to prevent ol processing hazards |

| louch screen input | Touch operation |

| Correction functon | Electrode deviation value can be manually input/automaticolly imported into the system, processing automaticaly reod the value |

| Coordinotes the memcry | Offset coordinate function |

| Auomatic memory functon | Automatic memory coordinates. no need to return to zero when power on, no need to return when power off custom] |

| Languope selection | Chinese, English |

| Alom infcrmotion prompt functon | The alarm message con be prompted when the equipment s abnormal and the alorm appears |

| Trarsport | Support USB/LAN |

| Automatic oill pump function | Users can customize the ol pump on/off mode |

| Shake function | |

| Free to shake | Usually the shape shakes the mode |

| Quadrant shaking function | Spherical electrode processing can ensure the accuracy of the sphere to the greatest extent |

| Lock swing function | Lockling depth and shaking |

| Segmental rocking function | Swing in sections at the current I-axis position (can improve efficlency and reduce loss) |

| The spherical shaking | Spherical electrode processing can ensure the accuracy ot the sphere to the greatest extent |

| Radiation shaking | Angle cleaning con etfectively improve the quality of Angle cleaning |

| The bucket shaking | Bamel electrode machining can maintain the accuracy of the bottom row |